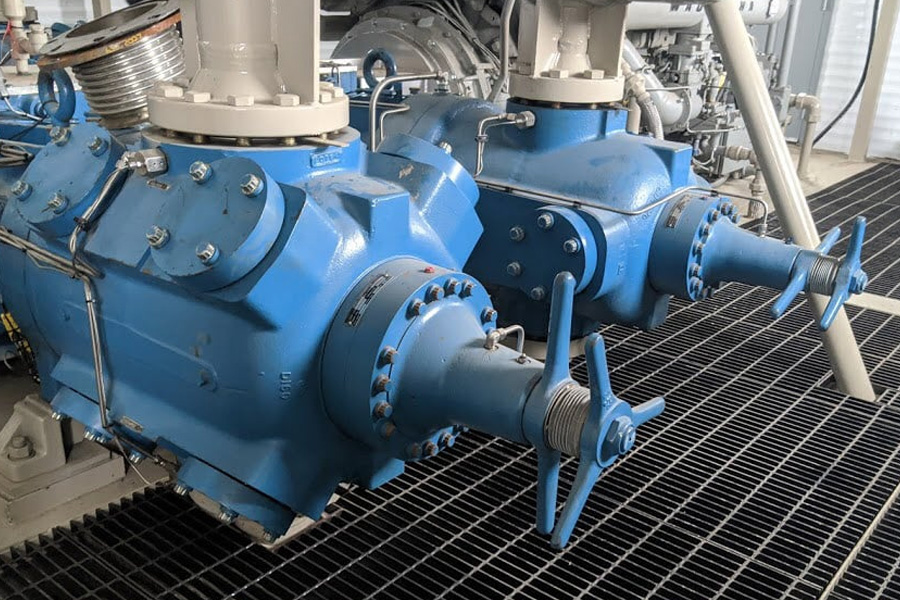

Reciprocating compressors are a cornerstone of many industrial applications, particularly in the refrigeration and air conditioning sectors. These powerful machines are designed to compress gas by reducing its volume, which is achieved through a piston-driven mechanism. Due to their reliability and efficiency, reciprocating compressors are widely used in various industries, from food processing to chemical manufacturing. For businesses that rely on efficient and consistent refrigeration or air compression, understanding the function and benefits of reciprocating compressors is essential.

How reciprocating compressors work

At the heart of a reciprocating compressor is a piston that moves within a cylinder. As the piston moves down the cylinder, it creates a vacuum that draws in gas through an intake valve. When the piston moves back up, it compresses the gas, increasing its pressure before forcing it out through a discharge valve. This basic yet effective mechanism allows reciprocating compressors to handle a wide range of pressures and flow rates, making them versatile for different industrial needs.

One of the key characteristics of reciprocating compressors is their ability to deliver high pressure levels. This makes them ideal for applications where a significant amount of gas needs to be compressed quickly and efficiently. Additionally, these compressors can be configured to handle various gases, including air, natural gas, and refrigerants, further broadening their range of applications.

Advantages of reciprocating compressors

One of the primary advantages of reciprocating compressors is their durability. Built to withstand the rigors of industrial use, these compressors are known for their long operational life. They are capable of handling intermittent or continuous duty cycles, which is crucial for industries that require reliable performance under varying conditions. The robust construction of reciprocating compressors ensures that they can operate effectively in demanding environments, providing consistent performance over time.

Another significant benefit of reciprocating compressors is their energy efficiency. While the initial cost of these compressors may be higher than other types, their efficient operation can lead to lower overall energy consumption. This is particularly important in industrial settings where energy costs can significantly impact the bottom line. By using a reciprocating compressor, businesses can reduce their energy expenditures while maintaining high levels of productivity.

Applications of reciprocating compressors in industry

Reciprocating compressors are used in a wide variety of industrial applications due to their versatility and reliability. In the food industry, they are often employed in refrigeration systems, where maintaining precise temperature control is essential for preserving the quality and safety of food products. These compressors are also used in the chemical industry, where they handle the compression of various gases used in production processes.

In addition to their use in refrigeration and chemical applications, reciprocating compressors are also found in the oil and gas industry, where they are used to compress natural gas for transportation and storage. Their ability to handle high-pressure requirements makes them ideal for these demanding tasks.

Moreover, reciprocating compressors are commonly used in air conditioning systems, both in residential and commercial settings. Their ability to efficiently compress refrigerants makes them a key component in systems designed to cool large spaces. The adaptability of reciprocating compressors to different gases and their ability to operate under various conditions make them a preferred choice across multiple industries.

Investing in reciprocating compressors

For businesses considering an investment in reciprocating compressors, it is crucial to choose equipment that meets the specific needs of their operations. Factors such as the type of gas to be compressed, required pressure levels, and the intended duty cycle should all be taken into account when selecting a compressor. Additionally, considering the long-term energy efficiency and maintenance requirements of the compressor can help businesses make a cost-effective investment that will serve their needs for years to come.

If you’re looking to enhance your industrial operations with reliable and efficient reciprocating compressors, visit Industrialfreezing.com. With a wide range of high-quality compressors and expert guidance, Industrial Freezing is your trusted partner in finding the perfect solution for your business. Invest in the best equipment today and ensure the long-term success of your operations.